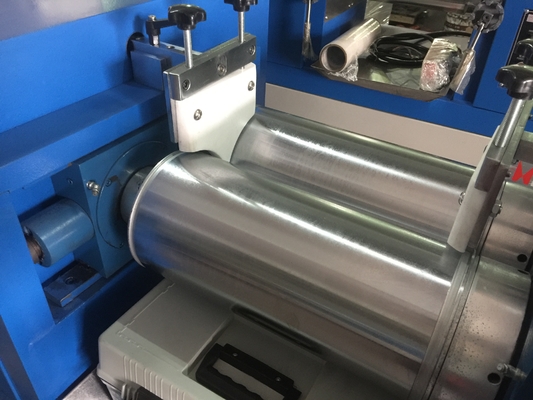

Rubber and Plastics Two Roll Mill Mixing Fining Mixer New Medical Supplies Machine

Application:

It is widely used in rubbers and plastics industry for polymer mixing, such as PVC, color master batch. It consists of roll, bearing, gap adjusting device, electric control system, safety device, etc.

ZL-3018 Two roll mill.pdf

When the rubber compound is processed on the open mill, what conditions should be met to obtain a good rubber mixing effect?

From the point of view of mechanics, study the conditions for the rubber material to enter the roll distance

In the rubber mixing operation, we can see that when the rubber material wraps a roller, there is still a certain amount of accumulated glue between the two rollers. The build-up glue continues to form. These accumulated rubbers have a great influence on the mixing effect.

If there is too much accumulation, the excess accumulated glue will not be able to enter the nip in time, and can only be shaken lightly in place, and the rubber mixing effect will be significantly reduced at this time.

If the accumulated glue is too small, stable and continuous operation cannot be formed.

It can be seen that it is necessary to determine the right amount of stacking glue.

Technical parameters:

| |

|

|

|

|

|

|

|

|

| Roll Hardness |

HRC 50 ~ 60 |

| Temperature Accuracy |

± 2 ℃ (we adopt the high accuracy PID micro computer controller)

| Model |

|

ZL-3018-76 |

ZL-3018-120 |

Zl-3018-160 |

ZL-3018-200 |

Zl-3018-230 |

Zl-3018-300 |

ZL-3018-400 |

| Diameter of roll |

mm |

76 |

120 |

160 |

200 |

230 |

300 |

400 |

| Length of roller face |

mm |

300 |

350 |

350 |

500 |

650 |

650 |

900 |

| Mixing Capacity |

kg |

0.002-0.6 |

0.002-2 |

0.002-2.8 |

0.002-5 |

0.005-10 |

1-15 |

5-30 |

| Front roll surface speed |

rpm |

19 |

19 |

19 |

19 |

19 |

19 |

19 |

| Friction ratio |

|

1:1.30 |

1:1.35 |

1:1.35 |

1:1.35 |

1:1.27 |

1:1.27 |

1:1.27 |

| Roll gap range |

mm |

0-3 |

0-6 |

0-6 |

0-8 |

0-12 |

0-12 |

0-15 |

| Driving Power |

KW |

1 |

1.5 |

2.2 |

7.5 |

11 |

30 |

37 |

| Heating Mode |

Electricity heating , Oil Heating ( option) |

| Cooling Mode |

Water Cooling ( option) |

| Roll Temperature |

Room temperature -- 300℃ |

|

| Safety device |

It have 6 safety buttons and safety guard is option |

| Machine weight |

kg |

160 |

460 |

660 |

860 |

1960 |

2960 |

3800 |

| Overall dimension |

mm |

1100x400x1180 |

1100x550x1380 |

1200x650x1380 |

2200x750x1380 |

2200x950x1580 |

2600x950x1580 |

5295x1789

x170

|

| Power |

380V 3 phase 50-60hz |

Advantage Service:

1. We have R&D, designing department which can not only provide technological machines but also can satisfy special customized needs of our clients.

2. Over 50 years’ manufacturing experience, advanced machine and sophisticated handcraft.

3. There are TWO laboratories in our factory: Environmental laboratory and Physical laboratory.

4. Our factory have adequate stock monthly, which can meet customers’ urgent needs.

5. Annual sales over 1,000,000USD; 30,000㎡manufacturing base, equipped with 120 technicians, we are capable to take large budget project.

Technical Support:

1. SUS Stainless plate is cut by advanced leaser machine which can ensure accuracy; All machine appearance is anti-rust electrostatic painting;

2. Imported electronic components: ABB/Siemens/Panasonic/Saginomiya/Danfoss/Emkarate/Omron and imported compressor:BOEK/TECUMSEH, which can keep the machine’s service life over 10 years.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!