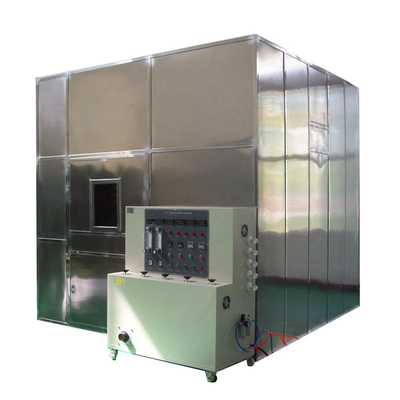

IEC 60331 BS 6387 BS 8491 Wire Cable Circuit Integrity Tester for Multi-Core Cable Testing Fire Resistance Burn Test Equipment

Technical Parameters:

1. Fire Resistance Test: (The fire resistance test bench includes the following parts)

1.1 Cable Support System

1.2 Continuous Detection Device

1.3 Heat Source

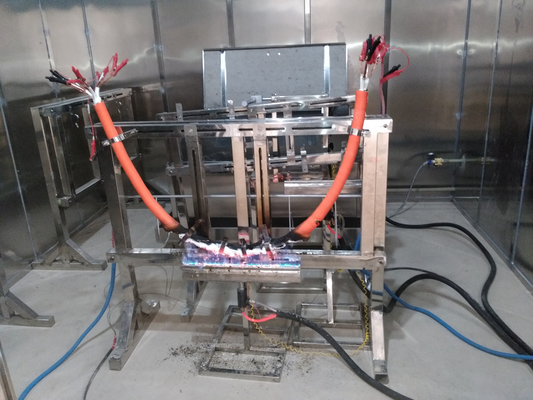

Cable support system: The cable is clamped horizontally at both ends of the cable sheath by a clamp. The middle part of the cable is fixed by two metal rings (300mm apart), and the metal rings are grounded to the other metal parts of the device. For unarmored cables with a diameter less than 10mm, or some other cables that are significantly displaced during the test, there are 3 metal rings, each fixed about 150mm from the original metal ring.

Continuous detection device: During the test, the current is passed through all the cores of the cable, a three-phase star-connected transformer or three single-phase transformers (or a single-phase transformer if the test is a single-core cable), and it has sufficient capacity to maintain the maximum allowable leakage current of 3A under the test voltage. At the other end of the cable, each core is connected to a lamp and a current of close to 0.25A is loaded at the rated voltage of the cable.

1.3.1 The heat is a 610mm long tube gas burner with forced methane and dense flame.

1.3.2 Temperature measurement: A 2mm diameter armored thermometer is placed near the air inlet, parallel to the burner 75mm above

1.3.3 Test Flame Temperature And Time: (see BS6387

combustion level)

A 650℃± 40℃ -3 hours

B 750℃± 40℃ -3 hours

C 950℃± 40℃ -3 hours

S 950℃± 40℃ -20 minutes

1.3.4 Sample: The sample is a section of the finished product, not less than 1200mm, with 100mm of sheath and covering removed at both ends. The wires at both ends of the cable should be connected in accordance with the electrical connection.

2. Water and fire resistance test: including the following parts

2.1 Cable Support System

2.2 Continuous Detection Device

2.3 Heat source

Cable support system: The cable is connected to a metal bracket composed of two 25mm wide steel plates, and the bracket is fixed with a metal clip with a spacing of 200mm. The cable is connected to the bracket and all metal frames are grounded.

Continuous detection device: During the test, the current is passed through all the cores of the cable, three single-phase transformers, and have sufficient capacity to maintain the maximum allowable leakage current of 3A under the test voltage. At the other end of the cable, each core wire is connected to a lamp and a current of close to 0.25A is loaded at the rated voltage of the cable.

2.3.1 Heat: A strip burner is 400mm long and can burn a 400mm cable sample. The burner assembly can be adjusted to provide a bright flame with a temperature of 650℃ ± 40℃.

2.3.2 Temperature Measurement: A 2mm diameter armored thermometer is placed on the lower surface of the cable

2.3.3 Test Flame Temperature: 650℃± 40℃

2.3.4 Water Spray: A nozzle is installed on the test bracket, in the middle of the burner. The water pressure is 250KPa to 350KPa, and 0.25 liters per square meter to 0.30 liters per square meter of water is sprayed near the sample. This rate needs to be measured with a collection tray, which has enough depth to make its long axis parallel to the axis of the cable and placed in the center. This tray is about 100mm wide and 400mm long (the device is shown in the figure below).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!