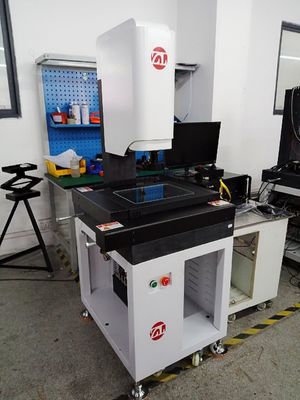

TPI precision screw Video Measurement Machine ( Automatic Economic type )

The image measuring instrument body and application features:

1, The main features of the automatic image measuring instrument:

◆ High-performance servo motor motion device to ensure high mute, high precision and high repeatability under high-speed operation of the instrument

◆ TPI precision screw, which makes the measurement positioning accuracy accurate and reliable, and the positioning accuracy can reach 0.001mm

◆ The column and base are made of high-precision granite structure, which is stable and reliable.

◆ Equipped with multi-function measurement software, which makes the measurement speed 4-5 times higher than the manual image measuring instrument.

◆ DXF files can be imported for fast detection, fast programming, batch measurement of products of the same specification.

◆ Measurement data can be imported into Word, Excel, AutoCAD, and report output functions, and easy to output test results.

◆ With automatic contour scanning, contour tracking, automatic product shape scanning and other functions.

◆ Z-axis adopts high-precision linear guide rails on the silver and X and Y axes to ensure high precision and service life.

◆ CNC high-definition lens and dedicated high-resolution CCD for high-definition measurement.

◆ The industry's advanced card position lens, easy to implement programming and program measurement, optional automatic zoom lens barrel.

2,Non-contact measurement of the advantages of automatic equipment: to avoid the original man-made testing methods caused by the "measured workpiece" human error, and can avoid artifacts caused by the test piece caused by secondary damage to ensure the workpiece under test products The quality of the stability and standard consistency. Can be several times to improve the detection efficiency of the production process, early detection and control of the production process of defective products, while reducing some of the cost of manual testing and improve product delivery timeliness.

3, The scope of application of the instrument: The measuring instrument can be applied to a variety of molds, aircraft, cars, mobile phones, computers, hardware, plastics, electronics, die-cutting, screen printing, LCP film, PCB, FPC, Cover, TP, ultra-large LCD monitor and other dimensional accuracy testing, and for reverse engineering plane research and development, design, drawing editing, laboratory and other required two-dimensional, three-dimensional detection and other auxiliary measurement industry.

4,The main function of the instrument configuration: The instrument is equipped with a dedicated image measurement software, high-definition color Sony CCD, high resolution 0.7-4.5 times (specific zoom times card position high resolution optical lens), specific computer, LCD, keyboard ,mouse (Option), digital measurement.

ZL-1502 Video Measurement Machine (Automatic type)...

Parameter:

| Model |

3020 |

4030 |

5040 |

| Stroke(mm) |

300×200×200 |

400x300x200 |

500x400x200 |

| Machine size (mm) |

850×1300×1500 |

1000x1400x1550 |

1200x1500x1550 |

| Metal Table size(mm) |

460X360 |

460X360 |

460X360 |

| Glass size(mm) |

340X250 |

340X250 |

340X250 |

| Machine weight (kg) |

250 |

350 |

450 |

| Glass table loading weight(kg) |

20 |

25 |

25 |

| X ,Y measure accuracy (μm) |

3.0+L/150 |

| Z measure accuracy(μm) |

5.0+L/100 |

| X,Y Axle Run speed |

0-200mm/S(selection) |

| Z Axle Run speed |

0-100m/S(Selection) |

| Repeated accuracy(mm) |

0.005 |

| Operation Mode |

software |

| Grating Ruler |

0.001mm Glass Rating |

| X,Y Axle Guide Rail |

- Domestic precision cross-anti-dislocation guide

|

| Z Axle Guide Rail |

Taiwan” Shangyin” H grade precision linear guide |

| Z Axle lead screw |

Taiwan TBI ” grinding ball screw |

| Bearing |

Japan original "NSK" double case combination centripetal ball bearing |

| Motor |

“TIGER”Ac synchronous servo motor, positioning accuracy ≤0.003mm |

| Motion Controller |

ZL4000(Full closed-loop controller) |

| Camera |

SBK-HC536 1/2inch 700 color high definition camera (with white balance function) |

| Video Card |

SV-2000High resolution color card |

| Light Source |

Rim Light |

Profile LED cold light source, transmission light and condenser lens to realize parallel light irradiation |

| Surface Light |

Four ring eight zone LED cold light source, software control, reduce electrical component damage. |

|

|

6.5:1 continuous variable caliper lens |

|

|

Optical Magnification:0.7~4.5×;Image image Magnification:24~158X |

|

Global Positioning System

|

Laser position indicator |

| Rocking Bar |

Germany ”MEGATRON”Hall triaxial joystick |

| Software |

Full Automatic + Probe software |

| Computer |

Industrial computer: Intel dual-core CPU,4G memory, 1000G hard disk, DVD drive, 2G independent graphics card, 19.5-inch display |

| Power |

220V/50Hz/3A |

|

|

Temperature 20 ℃ + 2 ℃, the temperature change < 2 ℃ / hr, humidity 30~80% |

| Special table for video equipment |

Built-in switching power supply, controller, motor driver, power control switch, indicator light, emergency stop switch, moving roller |

| Warranty |

12 months |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!