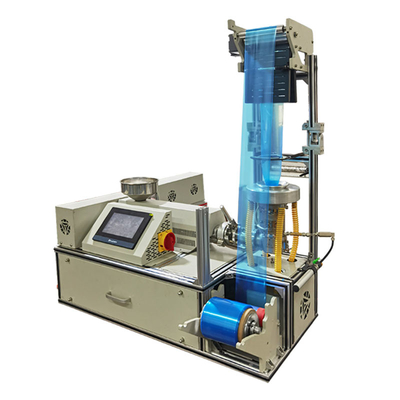

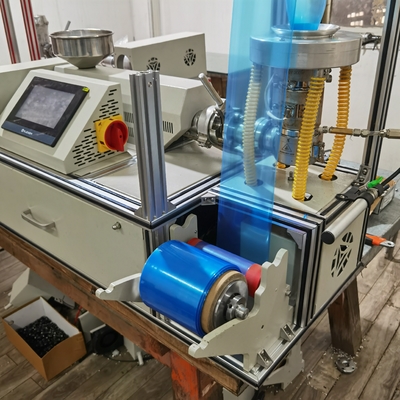

Desktop Lab Blown Film Machine

●Equipment Overview:

The Desktop Lab Blower is a small blown film machine for use in a laboratory environment, mainly used in research and development, small batch production and teaching experiments and other scenarios.

●Features:

1.Compact size: small footprint, easy to be placed on the laboratory bench, does not occupy too much space.

2.Easy to operate: usually equipped with simple control system, easy to operate and master, convenient for experimenters to adjust parameters and equipment operation control.

3.Precise control: able to precisely control the parameters of film blowing, such as temperature, speed, etc., to ensure the accuracy and repeatability of the experimental results.

4.Versatility: Different materials, thicknesses and widths of films can be produced by replacing molds of different specifications and adjusting process parameters to meet a variety of experimental needs.

●Application:

Material research and development: In the research and development of plastic film materials, it is used to prepare small batches of sample films in order to study the effects of different formulas and process conditions on film properties. For example, in the research and development of new polymer material films, film samples with different parameters can be prepared quickly by desktop laboratory film blowing machine to test its mechanical properties, optical properties, barrier properties, etc., which provides the basis for material optimization.

Process research: It is important for the research and improvement of blown film process. Researchers can use the equipment to explore the influence of different processing parameters, such as temperature distribution, screw speed, blowing ratio, traction speed, etc., on the quality and performance of the film, so as to optimize the blown film process and improve the quality and efficiency of film production.

Teaching experiment: It is one of the important equipments for teaching experiments of relevant specialties in colleges and research institutions. Students can operate the equipment to intuitively understand the process and principles of blown film, master the basic skills of plastic processing, and cultivate practical ability and innovative thinking.

●Technical Parameters:

| Screw diameter |

16mm |

| Length to diametar ratio |

1:30 |

| Blow film width |

50mm-130mm |

| Production efficiency |

1-2kg/h |

| Heating zone |

The whole machine adopts mica heating.wiih a heating time of 45 minutes |

| Volume |

(LxWxH):9200x520x1000mm |

| Folding volume |

(WxDxH):800x500x700mm |

| Power supply |

220v - power 3kw |

| Weight machine |

65KG |

| Blown film thickness |

0.03-0.15mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!