●Product Description:

This melt flow rate meter is an improved model with many functions added. It has greatly improved in terms of instrument configuration, instrument life, operation convenience, and test accuracy. It has incomparable advantages and advantages over domestic general melt flow rate meters cost-effective.

●Standard:

ISO 1133, ASTM D1238, GB/T3682

●Product Usage:

It is used to measure the melt flow rate MFR value of various plastics and resins in a viscous flow state. It is not only suitable for engineering plastics such as polycarbonate, polyarylsulfone, fluoroplastics, and nylon with high melting temperature, but also for polyethylene. (PE), polystyrene (PS), polypropylene (PP), ABS resin, polyoxymethylene (POM), polycarbonate (PC) resin and other plastics with low melting temperature are widely used in plastic production, plastic Products, petrochemical and other industries, as well as related colleges, research institutes and commodity inspection departments.

The melt flow rate meter is suitable for the determination of the thermoplastic melt mass flow rate specified in the national standard "GB/T3682-2000 Determination of Thermoplastic Melt Mass Flow Rate and Melt Volume Flow Rate". ISO 1133:1997 requirements, while meeting ASTM D1238 testing standards.

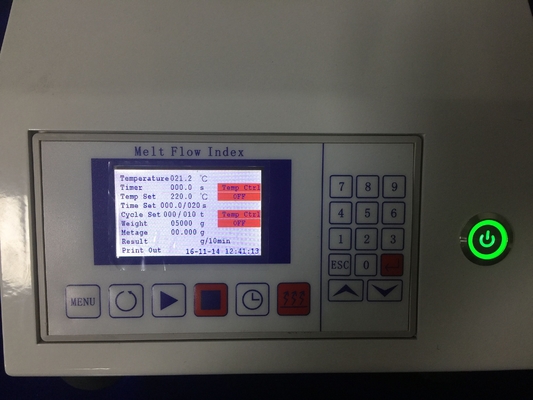

The melt flow rate meter is a desktop structure with reasonable design, stable and reliable performance, beautiful appearance, and convenient operation. It adopts high-performance, high-precision control instrument with high sampling accuracy and fast control speed. It uses fuzzy PID algorithm for constant temperature control.

●Features:

1.Fast heating speed and small overshoot.

2. High precision of constant temperature.

3. After filling, it can quickly restore the constant temperature state.

4. It is convenient to calibrate and modify the test parameters.

5. Manual and automatic material cutting test methods can be used.

6. Chinese liquid crystal display.

7. Equipped with a printer to automatically print out the test results.

●The Main Technical Parameters:

| Extrusion Discharge Part |

Outlet Diameter: Φ2.095±0.005 mm,

Outlet Length: 8.000±0.025 mm

Charging Barrel Diameter: Φ9.550±0.025mm,

Charging Barrel Length: 152±0.1mm

Piston Rod Head Diameter: 9.475±0.015 mm,

Piston Rod Head Length: 6.350±0.100 mm

|

| Standard Test Load |

A total of 8 levels of full set of weights |

| Temperature Range |

Normal room temperature - 400°C (500°C optional) |

| Constant Temperature Accuracy |

±0.5°C |

| Display Resolution |

0.1°C |

| Cutting method |

Manual or automatic cutting is optional |

| Temperature Recovery Time |

Less than 4 minutes |

| Printing |

Printing |

| Power Supply Voltage |

AC220V±10% 50HZ |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!