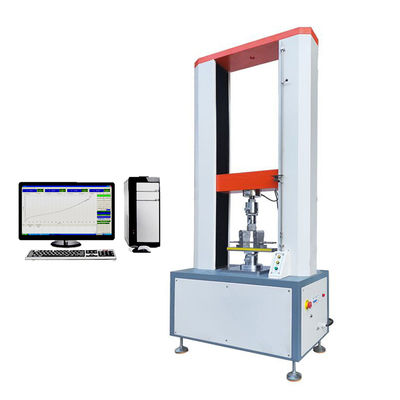

Dongguan Zhongli Instrument Lab Abrasion Torsion Bending Fatigue Strength Tester Electronic Auto Universal Testing Machine

Main Functions

This test machine is designed for testing flexible materials with large deformation such as rubber, plastics, leather, and others. It performs tensile, tear, adhesive strength, peel, and other tests. Equipped with a large deformative extensometer for specialized measurement of specimens, it is ideal for testing large deformation of materials.

Applicable Industries

Widely used in quality control across various industries including Rubber & Plastics, metallurgical iron and steel, manufacturing machinery, electronic equipment, automobile production, textile fiber, wire and cable, packaging materials and foodstuffs, instrumentation, medical equipment, civilian nuclear energy, civil aviation, colleges and universities, research laboratories, inspection arbitration, technical supervision departments, building materials, ceramics, Petroleum & Chemical, and other industries.

Corresponding Standard

GB/T16491-1996 Electronic Universal Testing Machine

Technical Parameters

| Model |

ZL-8001 Computer Servo Universal Tensile Strength Testing Machine |

| Max Load |

5KN, 10KN, 20KN (Can be customized) |

| Accurate Grade |

1% / 0.5% |

| Effective Measuring Range |

0.2%~100%(1grade)/0.4%~100%(0.5 grade) |

| Measuring Accuracy |

Display the value ±1%/Display the value±0.5% |

| Tester Resolution |

Max load 1/200000, regardless of inside and outside, constant the resolution |

| Load Sensor |

Basic configuration: sensor(max load): one. Extended configuration: can add more sensors |

| Effective Testing Width |

390mm (can be widened according to customer's requirement) |

| Effective Tensile Stroke |

800mm; 1000mm; 1200mm (can be increased the height according to customer's requirement) |

| Range of Testing Speed |

0.001~200mm/min; 500mm/min (1000mm/min is option) |

| Accuracy of Displacement Measurement |

Tolerance: ±0.5%/ tolerance: ±0.2% |

| Deformation of Measured System |

Min span: 10mm, Max range of deformation: 800mm. Extended deformation: Min span: 25mm, 50mm, 100mm, range of deformation: 5mm, 10mm, 25mm |

| Accuracy of Measured Deformation |

Tolerance: ±0.5% (according to requirement of customer to choose the larger or small deformation) |

| Safety |

Electronic-limit protection |

| Testing Platform Moving Device |

Fast/slow two speeds to control, can jog |

| Return Back |

Manual or automatic operation. After the test, the moving iron returns to initial position with the highest speed by manual or automatic operation |

| Overload Protection |

Overload 10%, automatic protection |

| Fixture |

A set of tensile fixture |

| Machine Size |

80x55x220cm (length*width*height) |

| Power System |

Panasonic AC Servo Motor + Driver + high-precision ball screw |

| Power Supply |

220V, 50HZ |

| Power |

0.4KW (depending on different demand of force, using different motor) |

| Machine Weight |

(about) 250 Kg |

| Units |

Kg, N, LB, TON, can be exchanged |

Equipment Summary

The Electronic Universal Tensile Test Equipment combines electronic technology with mechanical transmission, featuring accurate load speed, range of force measurement, high accuracy and sensitivity for load, displacement measurement and control. It can test constant-velocity loading and constant-velocity displacement. Simple to operate, it is especially suitable for quality control in production lines. This series is mainly applied to test non-metallic and metallic materials with loads less than 2 tons.

Items Tested in Computer Servo Testing Machine

- Tensile stress

- Tensile strength

- Rate of elongation at break

- Fixed stress

- Rate of stress at break

- Stress strength

- Tear strength

- The value of force at any point

- Rate of elongation at any point

- Pull-out strength

- Force of adhesion and the peak of force

Main Features

Features photoelectric encoder for displacement measurement, embedded single-chip microcomputer controller with multi-function software combining measurement, control, calculation, and storage. Automatically calculates stress, rate of elongation (with extensometers), tensile strength, elastic modulus, and statistical results. Records maximum points, breaking points, and designated point values. Computer displays dynamic curves during testing and processes data. Post-test analysis includes curve amplification through graphics processing module, report printing, and product performance at international advanced level.

Software Features

A. Standard modular function: Provides necessary applications for testing, covering GB, ASTM, DIN, JIS, BS and other testing standard specifications.

B. Tested product information: Allows data input about products for permanent reuse. Data can be automatically corrected by formula for improved accuracy.

C. Dual-Report Editor: Offers customizable report formats (testing program adds EXCEL report format, extending previous single pattern statements).

D. Exchangeable units: Length and force units can be exchanged (force: T, Kg, N, KN, g, lb; length: mm, cm, inch).

E. Auto-optimization of graphic scale: Displays best measurement graphics. Supports moving exchange in graphics with load-displacement, load-time, displacement-time, stress-strain, load-2 points extending maps, and multiple graph comparisons.

F. Test results output: Results can be output in EXCEL format.

G. Test result preservation: Results can be automatically or manually preserved. Automatically calculates maximum strength, yield strength, loop method, best method, non-proportional extended strength, tensile strength, compressive strength, tensile strength at any point, constant load extension, elastic modulus, rate of elongation, peel range of maximum force, minimum force, average force, total energy, bending modulus, x% load in break displacement, load X% in break displacement, etc. Data can be stored in any disk.

H. Data output capability: Software can output previous data.

Fixture Accessories Customization

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!