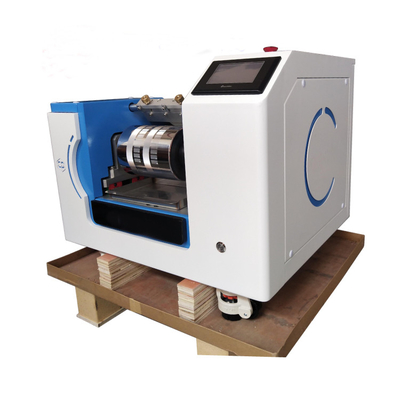

ISO 8791 Offset Ink Gravure Printing Proofing Machine

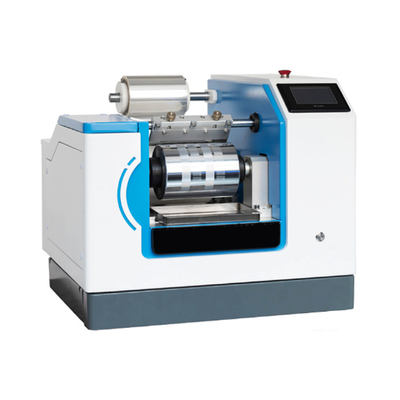

Advantages of Gravure Proofing Machine:

1. Use gravure anilox stick and scraper to supply ink.

2. The round pressed round structure is closer to the structure of the gravure proofing machine.

3. The proofing speed is closer to that of the gravure printing machine.

4. Coating and proofing are more repeatable than using wire rods.

5. The printing effect is comparable to that of gravure printing machine.

6. Easy to operate, automatic positioning and electric closing.

7. It is easy to clean gravure water-based ink.

8. The reticulated stick can be customized according to customer requirements and is easy to replace.

9. The printing plate can be designed so that half of the circle is a pattern plate and half of the circle is a white ink plate, which is convenient for white ink proofing (can be electronically controlled to automatically switch to white ink).

Scope of Application:

1. Applicable Plate Making Companies:

① Instead of manual ink scraping, spot colors can be quickly and accurately debugged under the same parameters of speed and pressure as the printing machine, greatly reducing the number and time of concave proof machine proofing.

② The company's process curve production is simple and convenient. The craftsman can quickly develop the color alone without the cooperation of the concave sample workshop.

③ The manuscript designer can also show the color to the on-site customer within 5 minutes, and the customer can see the final color printed on the finished product in the early stage of design.

2. Applicable Printing Companies:

① Instead of manual ink scraping, spot colors can be quickly and accurately debugged at the same speed and pressure as the printing machine, which greatly reduces the waste of ink adjustment on a high-speed printing machine.

② The colorimeter, combined with the colorimeter and color software, can greatly reduce the residual ink inventory of the printing company.

3. Applicable Ink Manufacturing Companies:

① Data management, color detection with spectrometer, and data report of color bar measurement.

② Cooperate with relevant instruments to test the abrasion resistance, fading resistance,

transferability, light resistance and heat resistance of the ink.

Product Specifications:

| Control Voltage |

24VDC |

| Power |

0.5KW |

| Maximum Printing Width |

110mm (customizable) *365mm |

| Printing Speed |

0---260 m/min |

| Machine Size |

630mm*550mm*550mm |

| Whole Machine Weight |

105KG |

| Accuracy |

Δ value is less than 0.5 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!